What is a sheet metal fabrication?

Views: 842 Update date: Jan 18,2024

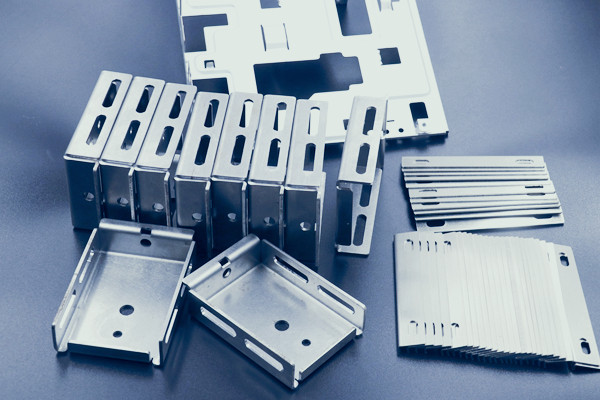

Sheet metal fabrication is a process of manipulating and shaping metal sheets to create a variety of products and components. This manufacturing technique involves cutting, bending, and assembling thin metal sheets to achieve the desired shape and specifications. Common materials used in sheet metal fabrication include aluminum, steel, brass, and copper.The process typically involves the following steps:

Bending: The metal sheets are then bent into the desired shape using tools like press brakes. This step is crucial for forming three-dimensional structures.

Forming: Additional forming processes may be applied to create specific features, such as rolling to create cylindrical shapes or deep drawing to produce complex curves.

Finishing: The fabricated product may undergo finishing processes like painting, coating, or polishing to enhance its appearance and protect it from corrosion.

Sheet metal fabrication is widely used in various industries, including automotive, aerospace, construction, electronics, and manufacturing. Products produced through this process can range from simple brackets and enclosures to more complex components used in machinery, vehicles, and architectural structures.