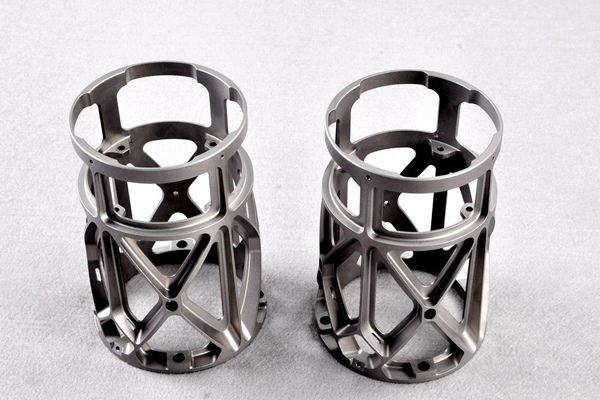

Using Titanium for CNC Machining

Titanium is a metal that is known for its unique properties, including strength, durability, and resistance to corrosion. These properties make it an ideal material for use in a variety of industries, including aerospace, medical, and automotive. Titanium material CNC machining services are a popular method for manufacturing precision parts and components from this material. In this blog, we will explore the benefits of using titanium for CNC machining, as well as some of the key considerations for working with this material.

Benefits of Using Titanium for CNC Machining

Titanium is an excellent choice for CNC machining for a number of reasons. First and foremost, it is an incredibly strong material, which means that it can be used to create parts that are durable and long-lasting. In addition, titanium is lightweight, which makes it an ideal material for applications where weight is a concern, such as in the aerospace industry. Finally, titanium is also highly resistant to corrosion, which makes it an excellent choice for use in harsh environments.

Considerations for CNC Machining Titanium

While there are many benefits to using titanium for CNC machining, there are also some important considerations to keep in mind. One of the key challenges with titanium is that it is a difficult material to machine. It is very hard, which can make it difficult to cut, and it is also prone to work hardening, which means that it can become even harder as it is machined. As a result, it is important to use the right tools and techniques when machining titanium.

Another consideration when working with titanium is that it is a highly reactive material. When exposed to air or other elements, it can form a layer of oxide on its surface, which can make it even more difficult to machine. To avoid this problem, it is important to use cutting fluids and other techniques to minimize the risk of oxidation.

Finally, it is also important to choose the right CNC machining service for your titanium parts. Look for a service provider that has experience working with titanium, and that uses high-quality tools and techniques to ensure precision and accuracy.

Conclusion

Titanium material CNC machining services offer many benefits for manufacturing precision parts and components. However, it is important to keep in mind the unique challenges associated with working with this material. By using the right tools and techniques, and working with an experienced CNC machining service, it is possible to create high-quality parts and components from titanium that meet the unique needs of your industry or application.