How to Make Medical Device Enclosure Prototypes

How to make a medical device enclosure prototype? In general, several processes are used in prototyping, as it's a complex assembly.

Injection molding - Injection molding offers unbeatable production rates and per-part costs. The tooling is expensive, however, so extreme care must be taken when designing parts intended for injection molding.

Sheet metal - If you want a range of surface finishes or coatings for your medical devices, sheet metal would be a better choice, as Sheet metal components are cheap, durable and suitable for many surface treatment.

CNC machining - You can have a wide range of compatible materials, when you choose CNC machining, which can provide you with high precision components to assure assembly relationship.

3D printing - When you have internal cavities and features not possible with other technologies, make them by 3D printing.

Partner with a Experienced Prototyping Manufacturer

The best method to achieve efficient manufacturing for medical devices is to partner with an expert in the field of medical device prototyping.

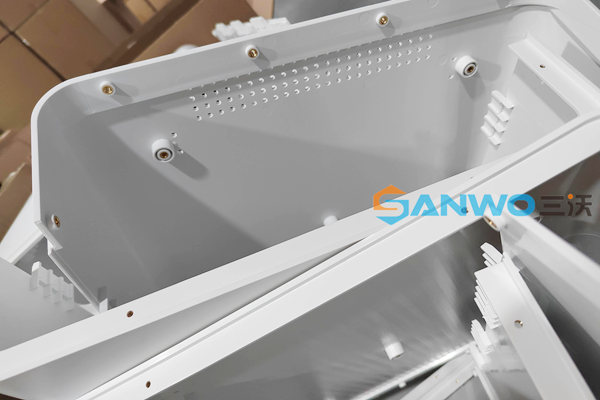

Sanwo has 11 year experience in prototyping. Sanwo Rapid manufacturing company gives one-stop supports of rapid prototyping & manufacturing services for clinical or medical device shell and enclosures as well as units. Among the many processes, Vacuum Casting is the very best option for the shells and coverings duplicates from one prototype model to low volume production in Urethane. Device parts from Hand grip model, rubber components, to Device shells and enclosures of Ultrasound machine, Ventilator, Carts, tables and panels, which the parts can be mold out as a single part without splitting and glued, and even over-mold with the waterproof Gasket, to ensure the strength, Function and assembly fitting for the Medical Device shells product.

Contact Sanwo for A Quick Quotation

After receiving your brilliant design files, our professional engineer team will analyze the issues and highlights of your medical devices based on our extensive experience and send you an accurate quotation at earlist.